Story of a family run

enterprise Spilker GmbH, where three generations have technically indulged to

grow their venture from humble beginnings

to attain success at global levels. They strive to upgrade and cater to customer

needs maintaining quality standards assuring reliability in German precision!

In 1963, Herbert Spilker, trained

as an engraving master, set up his startup venture in a small garage. Without

any equipment and relying on his engraving skills, he started engraving metal

brass plates for trophies with the barest minimum hand tools. With three

children to support, a son Andreas the present Managing Director of Spilker

GmbH born in 1961, another son and a daughter, he worked hard all by himself to

grow his maiden engraving enterprise. In 1970s he felt it was time to move

ahead. Self adhesive labels were evolving at a fast pace and the die cutting

process was in the process of transforming from flat bed die cutting to rotary

die cutting. Herbert Spilker wanted to produce flat bed dies but as luck would

have it, prospective customers were already considering moves into faster

converting process using rotary dies. They resisted his offer for flatbed dies

and advised him to consider supplying rotary dies which at that time were being

supplied by only two companies i.e. Kocher+Beck and Gerhardt (now merged

into Rotometrics). The delivery time was very long, almost 2-3 months. Herbert

was convinced that rotary dies was the business to be in. In 1978 he produced

his first rotary die engraved by hand for a company Ritter Etiketten, now a

part of the Rako Group since 2006. That was the beginning of an exciting

journey to success in rotary tooling.

The first step towards expansion

|

| Herbert Spilker |

In the late eighties the cost

of rotary dies was making label printers consider using the cheaper but slower

flatbed cutting options. The costlier solid rotary dies made it imperative to

sell labels at a higher price making it difficult to compete. Flexible dies developed

in America and much cheaper than rotary

dies, started being imported by others into Germany. These were instantly opted

for by label printers to maintain their production speeds and consistent quality.

Once in their new premises, in 1988, Spilker GmbH invested in equipment to

produce both magnetic cylinders and flexible dies. Andreas Spilker proudly

states, “No one taught us how to make these flexible dies and magnetic cylinders,

we learnt it all ourselves” he further added, “It was the need of our existing

customers, so the investment and development became an imperative”. The next decade

was spent in consolidating, growing the new business, expanding and making

renovations in whichever department it was needed. Herbert Spilker a farsighted

man understood the need to transfer management to the generation next at an

appropriate time. He mentored his son and transferred the power step by step

until 1998 when he decided to retire and hand over the reigns of his growing

business to his son Andreas Spilker, the present Managing Director. In 2003

Spilker installed their first machine for milling and sharpening rotary dies.

Till then dies were sharpened by hand. They were the first manufacturer to

offer rotary dies sharpened by machines. In 2004 the variabase anvil roll was

developed for adjusting the cutting depth. In 2005 flexible dies in bigger

format 860mm X 1050mm were developed. Spilker also has now capability to

produce magnetic cylinders in very wide width up to 2800 mm. In 2006 they developed their

first rotary die cutting machine. In 2008 they added another 3200 square meters

to their production shop floor. In 2013 the MEP (Mechanical Ejector Pins) dies were developed. In 2015

another 300 square meters hall was added to develop custom built die cutting

and laminating machine, such equipment was showcased at the Labelexpo Europe in

September 2017.

The Family in business

Spilker continues to grow and attain global success. Andreas, a technocrat himself and a hands on

|

| Andreas Spilker, Harveer Sahni, Henrik Spilker & Anika |

Getting over difficult times

|

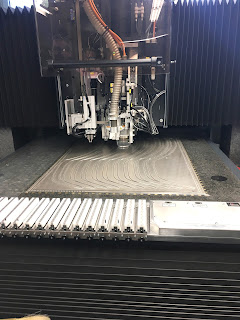

| Flexible die in production |

· Rotary tooling that include rotary dies and magnetic

cylinders

·

Flexible dies

·

Custom built machines

The above segments cater to the following industries;

· Labels and printing

·

Medical and Pharmaceuticals

·

Automotive supplies

·

Electronics.

|

| Magnetic Cylinder in production |

Andreas is pensive in his thoughts about his future in the company. He asserts that now that his children are getting firmly involved in the running of Spilker, in 5 years he will like to leave the management to them and retire. His daughter Anika is optimistic on the future and asserts that the company will grow further in both label and non label segments. Both Henrik and Anika are making efforts to expand into machine building while maintaining the quality and growth of existing business. Indulgent youthful attributes guided by an experienced mentor parent is sure to take Spilker to another level of success.

Written exclusively for Narrow Web Tech, Germany by Harveer Sahni, Chairman,

Weldon Celloplast Limited, New Delhi India May 2017

The article maybe published with the permission of Narrow WebTech Germany giving credit to them and to the author

For advertising inquiries please email to; harveersahni@gmail.com

The article maybe published with the permission of Narrow WebTech Germany giving credit to them and to the author

For advertising inquiries please email to; harveersahni@gmail.com